Biogas technology: a virtuous cycle

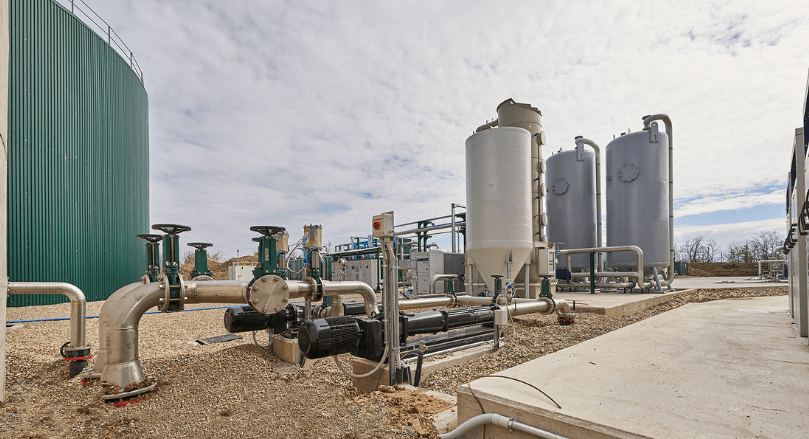

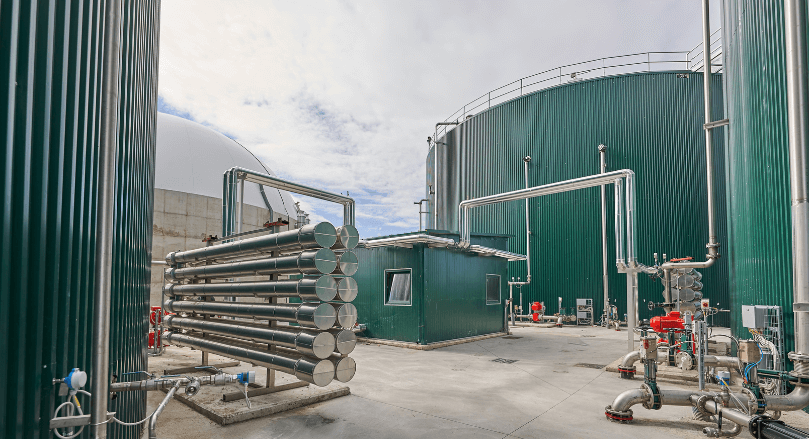

Biogas technology is an example of circular economy applied to renewable energy production. SEBIGAS implements anaerobic digestion technology, a biological process that takes place in the absence of oxygen and through which the organic content of

the biomass is transformed into biogas. This technology for biogas production is therefore based on natural processes for the recovery of waste and the production of renewable energy.

SEBIGAS’ know-how allows us to design plants by choosing from different technologies.

Starting with the biomass available to the customer, a more in-depth analysis is carried out and a preliminary mass balance is drawn up to understand the best biogas technology to be applies to each case.

The technologies proposed by SEBIGAS differ according to:

- DRY MATTER AND ORGANIC MATTER CONTENT of the biomasses;

- THERMAL REGIME functional to the best digestion efficiency (mesophilic, thermophilic, psycrophilic);

- Biomass RETENTION TIME in the reactor;

- MIXING SYSTEM that fits the best homogenization in the reactor.

The process in biogas technology

Biomasses used as inputs in the anaerobic digestion plants are diverse and come from the agricultural, industrial, waste, or sludge management sectors. Biomasses are loaded into the digester through a pre-tank or loader, following any pretreatment process.

The anaerobic digestion process takes place in digesters that are covered with a slab or gasometer cover, ensuring an appropriate storage of the biogas produced.

Energy from biogas technology

After appropriate treatments, biogas can be used to produce electricity and thermal energy from cogeneration, or separated to obtain biomethane and carbon dioxide for industrial use.

The electricity can be sold to the grid or used to power the plant itself and supply the company.

Thermal energy supports the heat balance of biological processes and it is a source of heat to power the plant’s external utilities.

Biomethane, on the other hand, can be sold to the natural gas transportation, to the distribution network or to CNG and LNG stations near the plant.

Digestate

Among the outputs of biogas technology is also digestate, a stream that can be valorised and processed for quality output. The digestate leaving the process serves a dual purpose in agronomic terms, as it makes mineral elements available to plants and contributes to carbon storage in our soils.

The digestate output can be separated obtaining a liquid and a solid stream. If necessary, the digestate undergoes on specific post-treatments aimed at recovering its soil improver and fertilizer capacity, or aimed at reducing the content of nitrogen and other pollutants.

The plant feeding

Flexibility, analysis and expertise enable SEBIGAS to suggest the best biogas technology to the customer, and to create a tailor-made recipe for treating heterogeneous and complex biomasses in anaerobic digestion. Many years of experience result in a portfolio of more than 70 analysed and managed biomasses that identify SEBIGAS as an experienced and reliable partner in the development and management of the plant.

Thanks to the biological and process services offered, SEBIGAS works on the best utilisation of the input matrices, guaranteeing the maximisation of results. In choosing the best reactor and the most efficient biogas technology, a precise and accurate knowledge of the biomasses available is importance, in order to assess their characteristics and quantities.

Biogas technology advantages

With the construction of a biogas plant, the company acquires value, becoming a protagonist in the fight against climate change and making its business more robust, sustainable and circular.

Installing a biogas plant allows your company to:

- Become ENERGY INDEPENTENT, producing electricity for self-consumption;

- Cocretely contribute to a SUSTAINABLE ENERGY POLICY, generating clean energy for the community;

- MINIMIZING THE WASTE MANAGEMENT COSTR of its production process.

DISCOVER THE BEST REACTOR FOR YOUR COMPANY!