Industrial biogas plants

Industrial biogas plants are a key technological solution for the agro-industry sector. As industrial production sectors are very energy-intensive, they would benefit greatly from the implementation of technologies supporting the circular economy and the reuse of energy. Indeed, these are productions that have high quantities of waste, both liquid and solid, which require high costs to be disposed of or recovered.

The technological proposals in the SEBIGAS portfolio make it possible to valorise different types of biomass, from dairies, breweries, distilleries, soft drink producers, sugar mills, paper mills and meat processing companies. An industrial biogas plant can become an opportunity for these companies to make a profit and make the production cycle sustainable.

Biogas in the industrial production

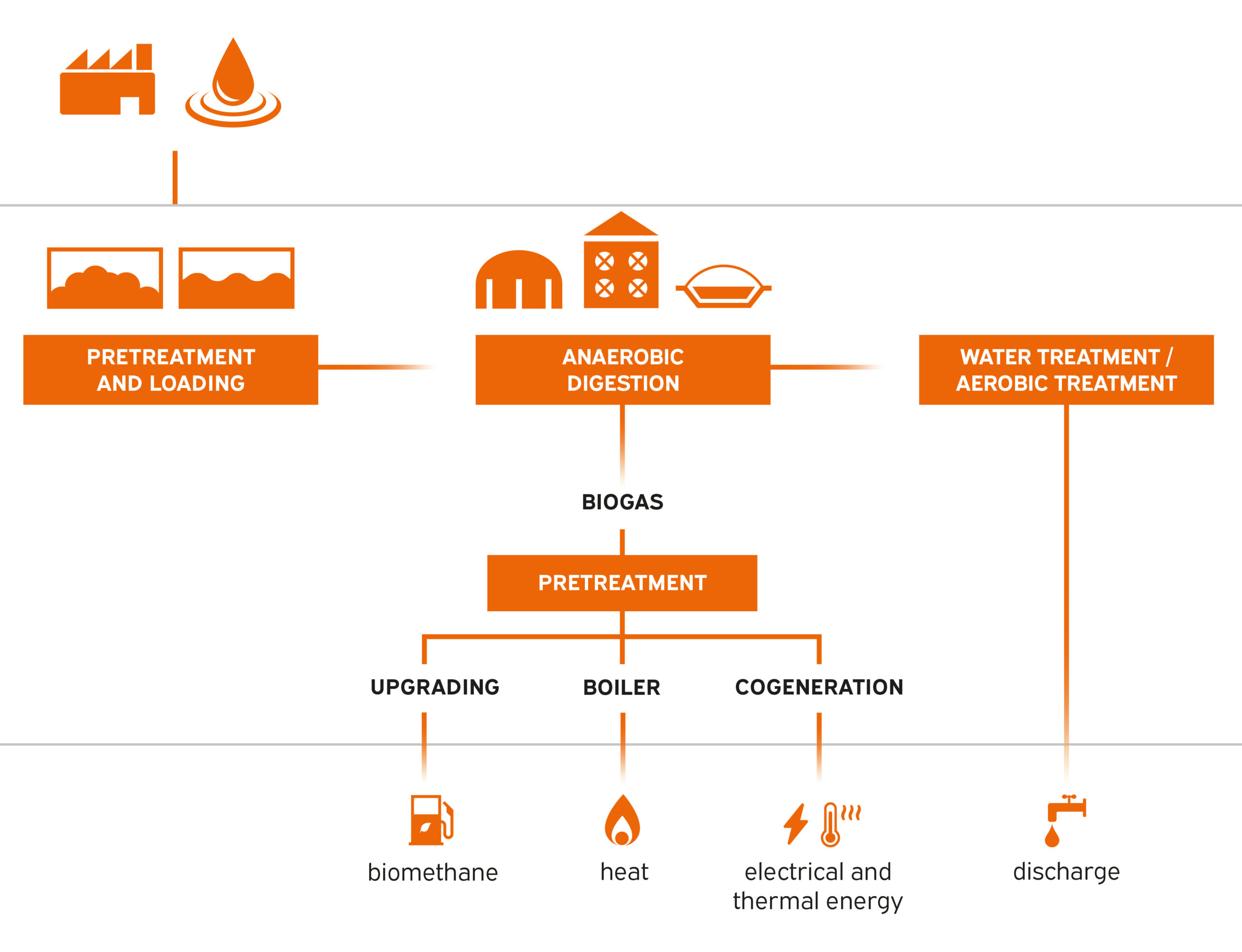

Thanks to the anaerobic digestion technologies proposed by SEBIGAS, companies can implement an environmentally and economically sustainable solution. The CSTR, anMBBR or CLR reactor is then suggested following an analysis of the biomass available to the customer, and their quantities, characteristics

and needs. A technology that contributes to the production of energy to be used directly in industrial production processes: a clear advantage in very energy-intensive production sectors with very high energy supply costs.

Environmental advantages

Thanks to this technological solution, the company makes its production processes environmentally sustainable. The waste produced during the production phases is very high and in most

cases is sent to disposal: through the anaerobic digestion, it is possible to enhance these effluents, creating a circular system of optimization and reuse of resources.

Economic advantages in industrial biogas plants

From an economic point of view, installing a biogas plant in industrial production processes is a source of considerable savings and advantages. This is even more evident if one considers that production is very energy-intensive, and consequently the amount of energy purchased from the grid is high.

By installing a biogas plant, however, the company can reuse the electricity for self-consumption, or feed it into the national grid with the incentive tariff. On the other hand, the heat produced by the plant can be used to meet the thermal needs of production.

FARMA HALASTRAS

Location: Salonicco (Greece)

Year of installation: 2018

Feeding: cattle slurry, slaughterhouse waste, expired food, beer production waste, whey.

Installed power: 1 MW

Use of electrical/thermal energy: The electricity is fed into the grid, the heat is used for heating the buildings, the pasteurisation system and the digester

Digestate: Used as an organic fertiliser for animal feed crops